High COD

Home > WWT Tech > High COD

Introducing

HYDRO-OXIDATION PROCESS TECHNOLOGY

Our team has developed an entirely different approach which addresses almost all the challenges encountered by use of conventional means of effluent water / fluid treatment.

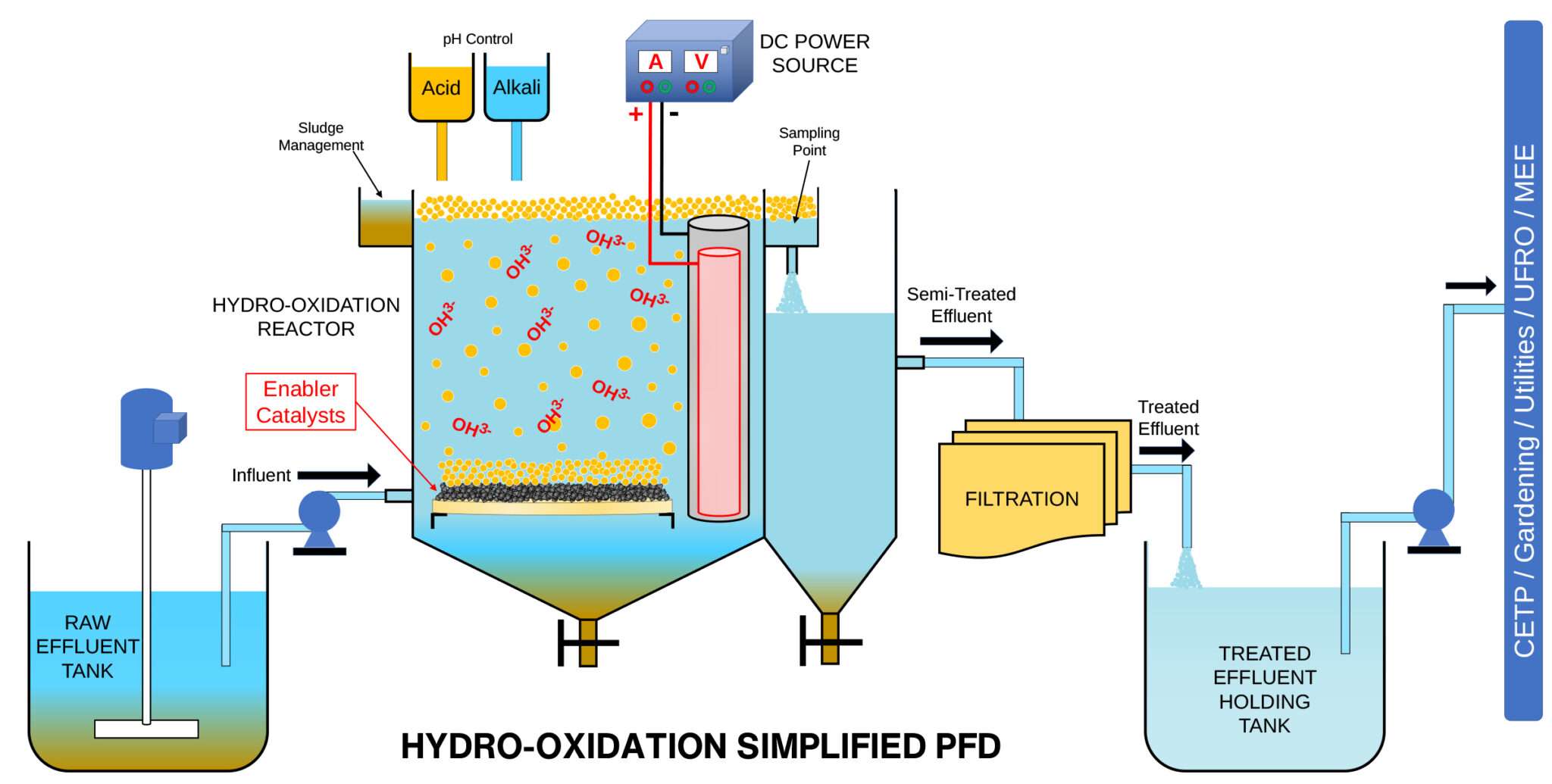

Rather than deploying a complex in-series multi-staged process that treats the effluent in various phases, our developed process system oxidizes a broad spectrum of pollutants within a singular process called Hydro-Oxidation (HO).

How Hydro-Oxidation Process Works

Our process technology involves treating the fluids through Hydro-Oxidation (HO) using its own especially in-house empirically developed metallic based ‘enabler’ catalysts, which release high potential molecular oxygen forcefully fed to the compounds within effluent fluid.

To achieve these simultaneous reactions, we have integrated our enablers within the HO process unit which create collisional forces (measured in angstroms) in the fluids to be treated. To support these collisional forces, certain radical accelerant solutions are also dosed into the process which are routed through our specially designed and controlled electrodes

Boson Alchemies HO Process = Effluent fluid + Enabler Catalyst + DC Current +/- Accelerants

HO Process

HO Process Steps

STEP 01

Raw Effluent enters into our HO process reactor (with or without pH adjustment).

STEP 02

With the assistance of the reactions that take place therein, the pollutants (organic and inorganic) in the effluent / process fluid starts to disintegrate out of the fluid molecule and coagulate into heavier particles which collect (depending on the density of the pollutants) either at the bottom of the reactor tank or at top of the fluid as floating sludge solids which are skimmed off or filtered out. For many effluents, during HO reactions, the dissolved solids may get oxidized and come into suspension.

STEP 03

The treated effluent is further fed to filtration equipment (either a filter press / screw press) for effective removal of any suspended solids.

STEP 04

Further, the filtrate is fed to tertiary treatment systems depending upon the end user requirement.

INLET to Futura HO Reactor = Effluent Fluids

REACTORS inside Futura HO System = Enabler +/- Accelerant + DC current

OUTLET from Futura HO Reactor = Pollutant Free Fluids + Sludge

Pollutants Removal Values

Avg % of Extraction / Separation / Removal

Our Scientific Approach to Effluents

We approach every affluent case methodically and scientifically. Before submitting a price quote, we require the client to provide us with a sample of their effluent, which we then run through our laboratory to ensure we can treat it effectively. Moreover, for Greenfield projects, we emphasize that the client must supply a synthetically produced effluent sample that is representative of their R&D.

A questionnaire is first received where we review the effluent characteristics, compounds present, problems statement, and the purpose very well with subsequent calls

Once we are convinced, only after we will request for effluent representative samples to be sent to our lab. Your effluent is subjected to multiple treatability studies and protocols to practically evaluate the best possible outcome and most optimized treatment protocol. A detailed report is tables with a complete basic design- PFD, Water Balance, and Lab Test Results with budgetary CAPEX and OPEX numbers.

In cases where the client wants to gain further confidence, we also offer on premise pilot trials for your effluent runs. Our pilot plants range from 1 KLD to 5 KLD capacity.

Finally a price quote is submitted after completing the treatability studies on your representative sample of effluent, along with PFD/Schematic, Water Balance, best possible commercially viable scheme, with firm CAPEX, OPEX, plant footprint with overall dimensions of key equipment.